By Elena Kornienko.

Once upon a time, there lived a widow woman and her son, Jack, on their small farm in the country. Every day, Jack would help his mother with the chores — chopping the wood, weeding the garden and milking the cow.

But despite all their hard work, Jack and his mother were very poor with barely enough money to keep themselves fed. And one day he was told by his mother to go and sell their cow and use the money to buy seeds to plant a good crop. On his way to the market he met a man who offered to buy the cow for three magic beans.

The boy did this deal, however his mother got very upset that he brought home only three beans…. Long story short, the magic happened and this family started making money and had a decent living. Fairy tale, right? We have been raised by so many stories like that, but did we relate any of them to our adult lives? Just last week I felt like this boy planting the magic seeds. The seeds of knowledge. The seeds to grow the expertise of local Iraqi companies which work with international oil companies (IOCs).

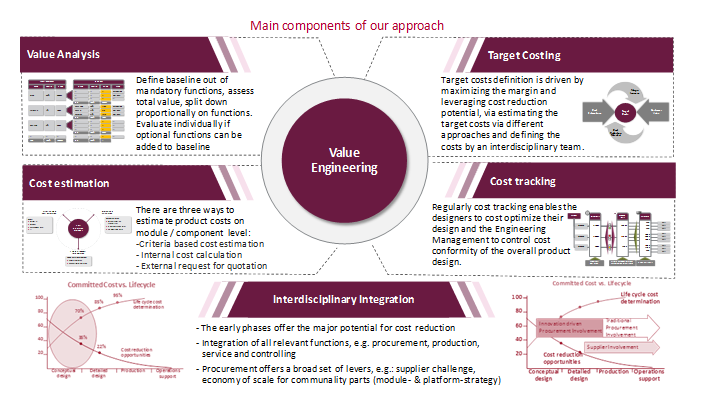

It’s no secret that upon completion of any tender exercise, most of the bidders do not get any feedback from Procurement team on what made them loose that contract. And in most of the cases it is not price, but the technical proposal itself. Even having all capabilities to perform services, most of the contractors struggle to understand how to put their proposals in the best way.

And Iraq, unfortunately, is not unique in that. It is a common situation that Procurement departments are detached from their bidders and contractors. Some of IOCs run workshops on understanding their specific requirements in tenders and systems, however what is still missing in the industry is a good education system for local contractors on requirements to tenders from IOCs.

Last week, 10th April 2018, the first training in Iraq on tendering skills for oil and gas contractors took place in Basra, which was run independently from IOCs. It was specifically dedicated to local Iraqi companies and all participants got to benefit from learning what exactly is happening in Procurement teams of IOCs operating in Iraq and what makes bids win the contracts.

It was the biggest surprise to all participants that 70 percent of bids do not even make through the technical evaluation, and Procurement teams do not even get to see their prices! And while this training was a matter of planting the seeds, the watering is still to happen.

From the left to the right: Majid A. Abdullah from Basra Chamber of Industry, Sabeeh H. Al-Hashemi, Iraqi Businessmen Union Basra, Elena Kornienko, InfoCORE Consultancy, Najih Shinawa Ahmad Alqanas, Basra Chamber of Commerce

From the left to the right: Majid A. Abdullah from Basra Chamber of Industry, Sabeeh H. Al-Hashemi, Iraqi Businessmen Union Basra, Elena Kornienko, InfoCORE Consultancy, Najih Shinawa Ahmad Alqanas, Basra Chamber of Commerce

After the training, the meeting with Basra Chamber of Commerce, Basra Chamber of Industry and Iraqi Businessmen Union took place to discuss the future opportunities for local companies. Whenever it comes to education and training, it is about the future vision.

It might seem that these three beans are too small for the exchange of a milking cow, but the magic of those beans should not be underestimated. All these organizations have a great understanding of the importance of the development of local Iraqi companies, and agreed to provide support in conducting future training sessions for local companies in Basra.

What was unique and magic about that meeting is the understanding that all participants are on the same level of grasping the needs of local companies development. It was planting those magic beans and start watering them to grow the capabilities of local Iraqi contractors to make the economy of Iraq more sustainable.

Elena Kornienko has more than 15 years of professional experience in contracts, procurement and tendering in various roles from demand-identification to contract close-out. She has worked on major international oil and gas projects, including the Sakhalin-1 and Sakhalin-2 fields in Russia, and Iraq’s West Qurna-2. Now based in Dubai, she provides consultancy services to the oil and gas industry. Elena is a fluent English and Russian speaker, and a graduate of the Moscow State University of Commerce, holding a degree in Economics. She also graduated with distinction from the School of Business Administration at Portland State University and holds a CIPS diploma.